Capture Coating™

Capture Coating™ is designed and formulated for all types of HVAC air filter media using patented nanotechnology that imparts superhydrophobicity, non-toxicity, and breathability without affecting airflow, energy efficiency, and HVAC equipment. Capture Coating is a penetrating sealer – it soaks into the surface of the material and forms a strong protective barrier under the surface without changing the airflow or breathability of the material. Once that barrier has formed then the amount of water that can soak in is significantly reduced. When applied to air filters, the coating does not change the MERV ratings of the filter.

How it works

When Capture Coating™ is applied on appropriately-rated HVAC air filters, it enhances air-filtration performance by functionally modifying the surface of the individual fibers comprising the filtration media. This establishes an environment at the filtration media-air interface conducive to an enhanced filtration efficiency of aqueous virus/microorganism carriers (e.g., infectious respiratory droplets) beyond manufacture-rated efficiencies via hydrophobic and electrophoretic interaction-based adsorptive filtration, as opposed to size-exclusion methods.

Capture Coating™ is partially composed of non-migrating material that prevents the growth of odor-causing microorganisms and does not foster the conditions that promote the viability and proliferation of viruses like SARS-CoV-2 and other contagion-causing microbes in the form of aqueous virus/microbe carriers expelled from infected individuals and/or animals. When properly used and applied, Capture Coating™ will yield a bacteriostatic, fungistatic, and algistatic surface on the air filtration media substrate to prevent deterioration and discoloration caused by fungi, algae, and odor-causing bacteria.

Independent testing

Capture Coating™ is a nanoscale system that conformally wraps around individual filtration media fibers, functionally enhancing their virus-carrier filtration performance without affecting energy efficiency or breathability which is spectroscopically detected and are shown in Figure a-c. Real-time quantitative polymerase chain reaction (RT-qPCR) studies using SARS-CoV-2 designed to simulate airborne transmission through HVAC air filters repeatedly show that MERV-8 tri-pleat filters treated with Capture Coating™ outperform MERV-14s, where cycle quantification value indicates less virion transmission through the filter (Figure d).

Figure: Optical micrographs of a) pristine and b) Capture Coating™-treated cotton fabric. The line arrays of overlapping blue markers demarcate where sequential optical-photothermal infrared (O-PTIR) spectra were collected, as magnified by the insets. c) Averaged O-PTIR spectra of pristine (black) and Capture Coating™-treated (green) cotton, corresponding to panels a and b. d) Cycle quantification values from RT-qPCR test results simulating airborne virion transmission through HVAC systems.

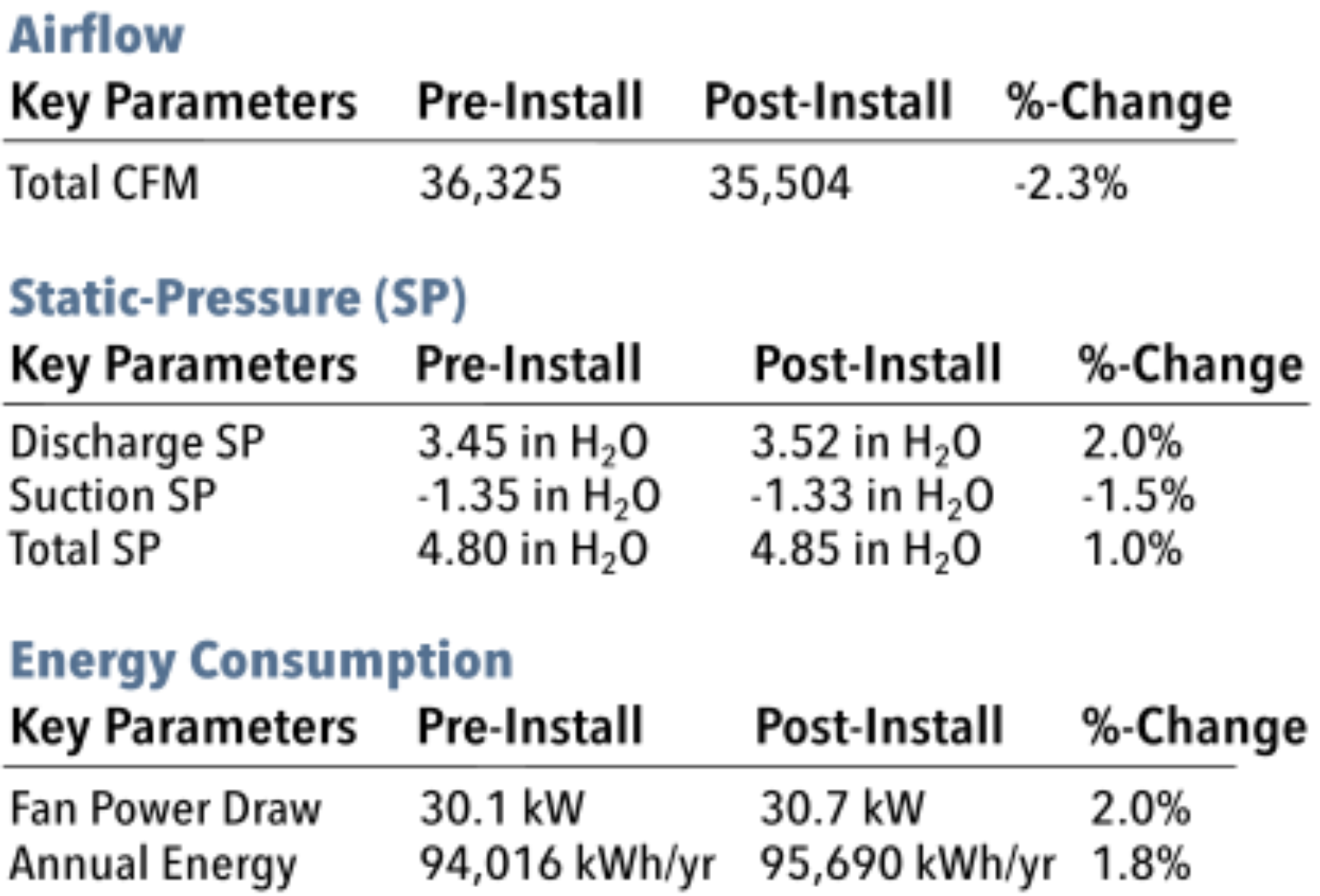

Independent studies retained by the Department of Citywide Administrative Services for New York City (NYC) demonstrate how Capture Coating™ negligibly affects (within measurable uncertainty) airflow, static pressure, and energy consumption using an air-handler unit outfitted with 20 MERV-8 tri-pleat filters supplying a NYC Family Court Service building, as specified in the table below.